“Nylon Fabric” – the words are very known to you, aren’t they? Well, I’m helping you by giving you the clue to remember it. Activewear? Still not ringing the bell? Then let’s try more. Sportswear, raincoats, hats, swimwear, carpets? Now got it? Yes, I think you did. You may have seen these words in any activewear. However, nylon is one of the most useful synthetic fibers in the world.

But do you know, what nylon is, what is nylon fabric made of, what is nylon fabric like, what is nylon fabric used for, how it is manufactured, and many more questions about it? Don’t worry, I am going to cover what is nylon and everything in detail about it in this article.

What is Nylon Fabric?

Nylon is a synthetic fiber that is derived from different natural fossils such as coal, water, petroleum, and others. Nylon fabric is considered one of the most useful synthetic fibers in the world. You may have known that this synthetic means nylon fiber was invented in the early 1930s.

In a general sense, nylon is an artificial fiber that is durable, strong, and able to resist abrasion. Due to huge demand, about 8 billion pounds of nylon are produced each year only in the U.S. Besides, other countries like China, Taiwan, and Japan produce nylon fabric as well. It has existed in our lives like an inseparable part.

Chemically, Nylon is made of polymers known as polyamides which contain different many substances like carbon, oxygen, nitrogen, and hydrogen.

So, in a word, nylon is a combination of chemical substances used in hundreds of thousands of sectors in our daily lives. It has a huge demand all over the globe.

Unlike other organic or semi-synthetic fibers, nylon fibers are entirely synthetic. It means they have no organic elements in their construction. In this case, polyester is also a solid synthetic. Do you know what polyester is? Well, if you know nylon very well, you will know polyester as well.

Are you now curious about what is nylon fabric made of? Well then, let’s dig more.

What Is Nylon Fabric Made Of?

As mentioned before nylon is a synthetic fiber that is created artificially through some processes. However, nylon fabric is made of different natural resources like coal, air, water, and petroleum. Through a specific procedure, nylon thread is made and then used for different purposes. This artificial fiber makes our lives easier and more comfortable. if you want to make heavy-duty tool bags for plumbers, nylon fabric would be preferable.

Who Invented The Nylon Fabric First And When?

Long story short, nylon was first invented in 1931 by an organic chemist called Wallace H. Carothers following the original patent of DuPont. This synthetic was manufactured after a long period of research and experiment to develop a new fiber that can replace silk. Silk is always very costly and a natural fiber. However, producing nylon introduced a revolutionary change in the apparel world.

However, the American Dupont company started manufacturing nylon and brought it to the public at the New York World’s Fair in 1939. To add more, by 1969 DuPont had invented seventy different types of nylons which was an epoch-making history. You may know that in 2005, Nylon even landed on Saturn’s moon, Titan.

The artificial fiber, Nylon, hasn’t come in this position in a day. It has, certainly, a long history behind it. To tell the short story is that it is a contraction of the name of the two world-famous cities- New York and London. If you need to know so much detail, you can read other articles.

Why Was An Alternative Fiber (Nylon) Necessary?

Before World War II, silk, cotton, and wool were the main and organic fibers to maintain the necessities of the people. Well, when WWII was started cotton had to play an important role. At that time, cotton was used for more than 80 percent of textile applications in the United States. And the rest of the necessity was filled up with wool. So, the pressures on cotton and wool were inexpressible. As they were natural, it was sometimes impossible to produce that huge amount of cotton and wool due to the scarcity of natural resources. This urged a new and alternative fiber.

However, as the patent was invented before the Second World War, by 1945, synthetic fiber like Nylon constituted around 25 percent of the textile market share. And when the war ended, a new era of synthetic fibers started and with it, new companies and manufacturers sought new ways to market this new class of synthetic fabrics.

Besides, immediately after WWII, there was a shortage of traditional dress materials like silk, cotton, and wool, and this is why some individualists tended to make dresses from repurposed nylon parachutes. Thus the idea to use nylon in women’s garments gained popularity. From this time, the production of nylon stockings and lingerie rapidly picked up steam.

How Was The Word ‘Nylon’ Derived From?

The DuPont Corporation brought the artificial fiber to the public and officially announced it at the 1939 World’s Fair.

However, at the time of its unveiling, Nylon did not have its current name. DuPont, at first, decided to market it under the name “no-run”. The thought was brought up in the mind due to its perceived ability to resist “runs” because when the fabric was used, the forms of damage to tights caused these garments to become aesthetically displeasing.

But, in fact, the notion soon proved wrong and essentially, the Nylon was subject to runs, and then a new name was given which is “Nuron”. The name seemed still unsatisfactory, so the name was again changed to “Nilon”. This time the name was okay but, to clarify the pronunciation the ‘i’ was replaced with a ‘y’, and finally, the name of the synthetic became “Nylon”.

The Manufacturing Process of Nylon Fabric

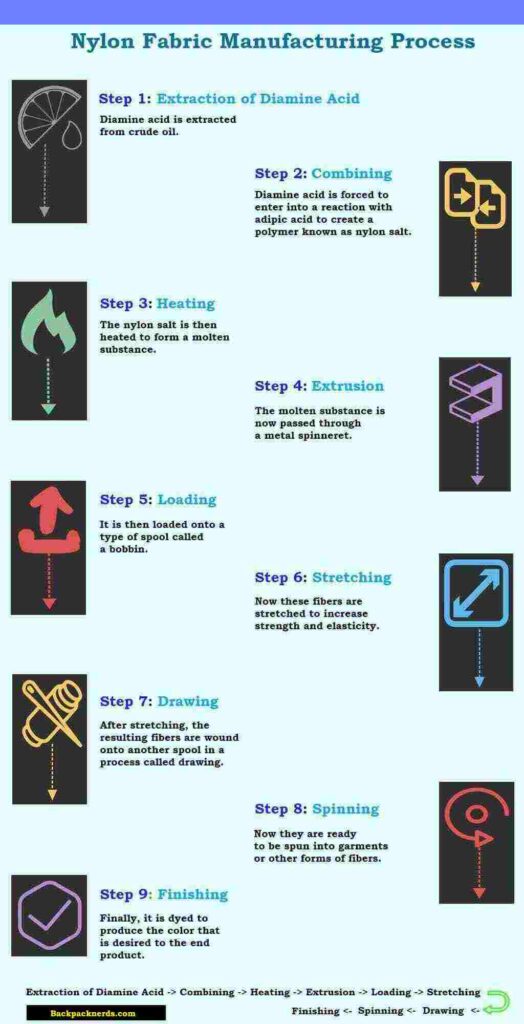

To manufacture nylon, there are some steps to maintain. In this section, I will elaborate on the process of producing nylon.

First of all, we know nylon fabric is made of polymer. Polymer is created by monomers which is a composition of a long chain of carbon-based molecules. There are many categories of nylon, but most of them are derived from polyamide monomers. These polyamide monomers are extracted from crude oil, which is also known as petroleum.

However, in most cases, a monomer is called hexamethylenediamine which needs to produce nylon. This substance (hexamethylenediamine) is shortly called diamine acid.

At this stage, to create the polymer (nylon), diamine acid is forced to enter into a reaction with adipic acid. This type of polymer is commonly known as PA 6, 6. And yes, it was the first type of polymer that was used for nylon fabric. The PA 6, 6 is also called nylon salt because it looks like salt and is clear like crystal. Now, it is time to heat this crystallized substance to form a molten substance.

Then, this molten substance is extruded through a spinneret. Now, what is spinneret? Well, the spinneret is a device that looks similar to a showerhead that has dozens of tiny holes. When the resulting fibers come through the spinneret, they immediately harden and are ready to be loaded onto bobbins.

Now, these fibers are stretched to increase their strength and elasticity. After this procedure, the resulting fibers are then taken into another process called “drawing”. Finally, this process makes the polymer molecules arranged in a parallel structure so that the resulting fibers are ready to be spun into garments or other forms of fibers.

The Properties of Nylon Fiber

Due to some amazing features, nylon fiber is good for people. These properties are not available in cotton or silk. Okay, let’s see the properties.

| Features | Results |

|---|---|

| Fabric name | Nylon |

| The fabric is also known as | Polymer fabric |

| Fabric composition | Various types of synthetic polymers |

| Fabric breathability | Low breathability |

| Tensile Strength | Excellent |

| Resilience | Excellent |

| Elasticity | Excellent |

| Abrasion Resistance | Excellent |

| Flame Resistance | Does Not Burn (in Normal Temperature) |

| Moisture-wicking abilities | Medium |

| Heat retention abilities | Medium |

| Absorbency | Fair |

| Static Resistance | Medium |

| Stretchability (give) | High |

| Wrinkle Resistance | Excellent |

| Resistance to Sunlight | Poor |

| Prone to pilling/bubbling | High |

| Country, where the fabric was first, produced | United States |

| Biggest exporting/producing country today | China |

| Recommended washing temperatures | Warm |

| Commonly used in | Tights, stockings, sportswear, yoga pants, and other form-fitting types of apparel |

Seeing this property you will easily understand what can this fabric or not. Important features like tensile strength, abrasion resistance, resilience, elasticity, heat resistance, and many more are favorable to all of us.

Who Is Nylon Fabric For?

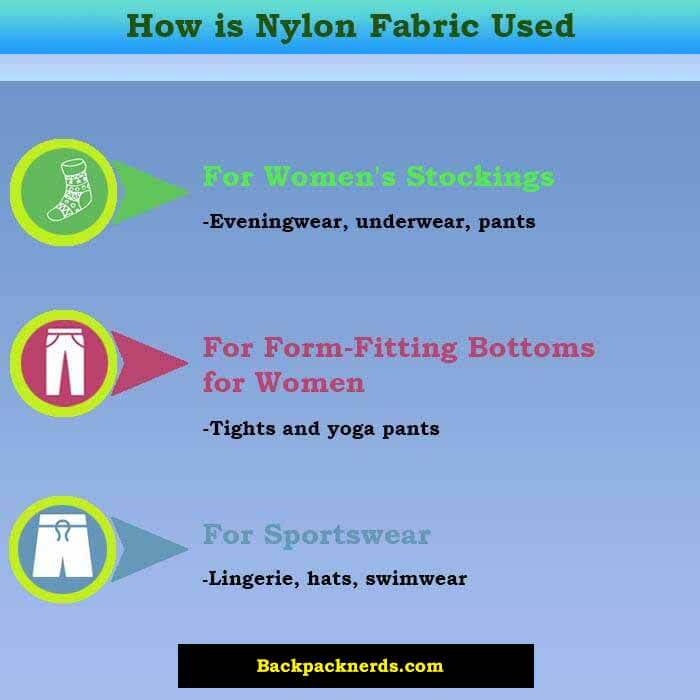

Nylon fabric was evolved as an alternative to silk, cotton, and wool stockings. Before spreading up this synthetic fabric, silk was the only viable material for sheer stocking. It was popular with women in the developed world. But, unfortunately, silk is not durable as well as notoriously expensive.

In today’s world, you have to live your entire life with nylon by your side. Where don’t you find nylon? Knowingly or unknowingly, we are using nylon even when we are walking across nylon carpets. When you are using a nylon toothbrush you are using nylon as well. At the time of rain, you use an umbrella- what is it made of? Yes, nylon. Even when you are wearing a swimsuit in the summer, it is made up of nylon. This is how we live in a life that is surrounded by nylon.

Later on, while nylon was available to people, it became a favorite stocking material among professional and domestic women. To this day, nylon is vastly used in women’s major applications such as tights, yoga pants, and other types of form-fitting bottoms for women.

Moreover, Nylon is commonly used in sportswear while other organic or semi-synthetic fibers are not really suitable for this application. Due to stretchability, durability, wick moisture capability, and other important functionalities, nylon is a great fiber for manufacturers as well as users.

Apart from this, sometimes sportswear manufacturers blend nylon with other fabrics to enhance elasticity, durability, and lightness.

Where Is Nylon Fabric Produced?

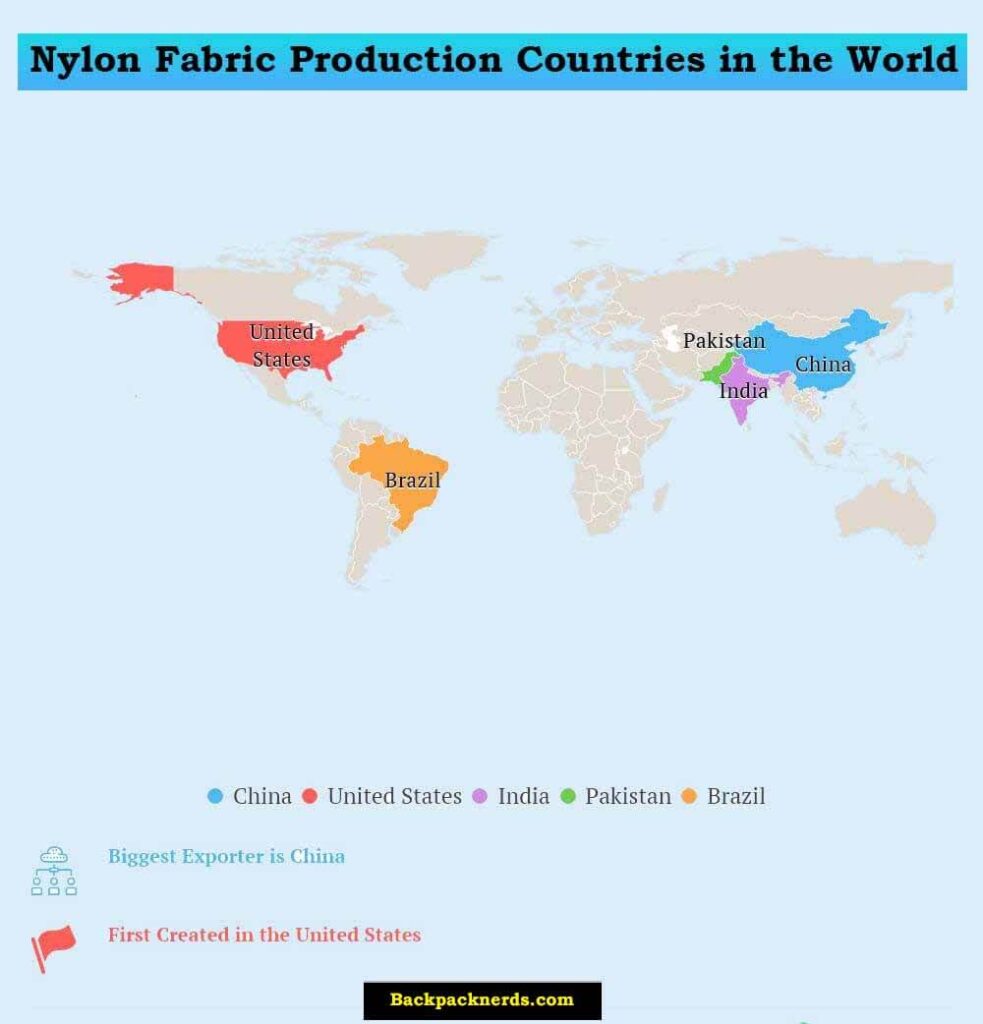

The USA was the harbinger to introduce nylon. This artificial synthetic was originally developed in the United States by the DuPont Corporation. They used to produce this fabric locally until the latter half of the 20th century. Later on, when the benefits of the fabric spread over the world, other developed nations came forward to produce nylon. It is also undeniable that the USA remained the primary producer of this fabric until the 1980s.

Towards the 1980s, many international corporations started following China as a manufacturing base, and consequently, many nylon fabric production operations moved to the East Asian country. Other regional nations that manufacture nylon are India, Pakistan, and Indonesia.

Different Types of Nylon Fabric

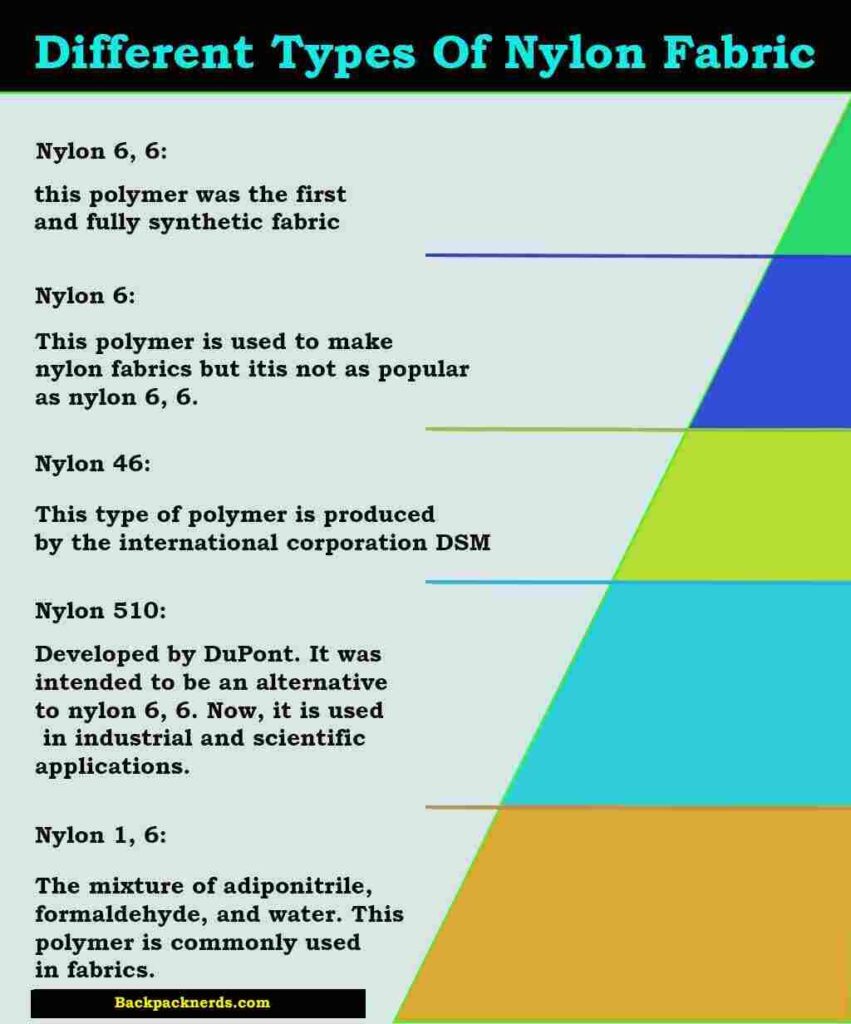

There are quite a few chemically different polymer substances. Those are called nylon. DuPont had invented seventy different types of nylons. However, some examples of these types of fabrics include:

- Nylon 6, 6: This polymer was the first fully synthetic fabric. It was a combination of diamine and a form of dicarboxylic acid.

- Nylon 6: this polymer is used to make nylon fabrics but it is not as popular as nylon 6, 6.

- Nylon 46: this type of polymer is not used for clothing purposes and is only produced by the international corporation DSM. It is commonly seen in engine components such as transmissions, brakes, and air cooling systems.

- Nylon 510: developed by DuPont. It was intended to be an alternative to nylon 6, 6. Now, it is used in industrial and scientific applications.

- Nylon 1, 6: the mixture of adiponitrile, formaldehyde, and water. This polymer is commonly used in fabrics.

Besides these, there are a lot of polymers that can be used for different purposes. The manufacturers manufacture nylon according to their needs and plans.

Characteristics and Features of Nylon Fabrics

There are some great characteristics that nylon fibers possess. You must appreciate it once you see it. So why late? Let’s see what characteristics and features of nylon fibers are waiting for us.

The Nylon Fabric –

- Very resilient because it springs back into its shape again

- Resists abrasion but can pill

- Durable and lightweight

- Heat resistant but very high heat can melt the fabric

- Resists wrinkling

- Dyeing color doesn’t fade easily like other fabrics

- Soft and lustrous and smooth in surface

- Does not shrink or stretch through washing

- Due to elasticity it can bend and bounce back

- Non-absorbent fabric

- Easy to wash and wear

- Resistant to mildew, molds, insects, and fungi

- Attracts static electricity

- Also attracts dirt and lint

- Can produce static electricity

- Due to low permeability, it can retain warmth

- Very strong fiber

- Nylon can be blended with other fibers like cotton, wool, etc.

- Dries very quickly

The Fun Part –

- The fun part is Nylon fabric does not absorb water but they do absorb oil and grease

- It resists soiling but once an oil-based stain soaks in, it can be difficult to clean

- Nylon has a high melting point. (melting temperature of 256°C/450°F)

- Nylon surface can be water resistant and made waterproof with coating

- Nylon is low cost, though costlier than polyester

- Nylon fibers can be spun as fine as silk

Remember, nylon fiber can be created both into Monofilament Yarn and Multifilament yarn. Monofilament yarn consists of a single strand of nylon fiber while the multi-filament yarn consists of several strands of thin nylon fibers that are twisted together to make a 20 or higher denier single yarn of Nylon. There are many categories of Denier like 500D, 600D, 1080D, 1600D, and many more. And it is obvious that multifilament yarn is stronger than Monofilament yarn.

Advantages and Disadvantages of Nylon Fabric

Undeniably, every product has good and bad parts. In this way, the excellent strength and abrasion resistance Nylon fabric have beneficial parts besides its drawbacks. Let’s discuss more it.

Advantages

Cost-Effective Fabric

Nylon is one of the most cost-effective fabrics on earth due to its available ingredients near your hand. These ingredients are also processed to make them suitable for forming nylon. Though nylon is cost-effective polyester is cheaper than nylon. This is why some producers prefer polyester.

Durable and abrasion-resistant

Due to nylon’s structural bonding, this synthetic is very durable. It is abrasion-resistant too. This fabric can withstand any inconvenient situation. For this reason, heavy-duty backpacks, parachutes, racket strings, sleeping bags, and hundreds of other products are made of nylon.

Resilient, soft, and lustrous

Nylon fabrics especially monofilament yarns become very soft and comfortable. It is also resilient and lustrous. Various kinds of designs and impressive colors make nylon fabrics lustrous. Due to its large use all over the world, this artificial fiber is great.

Heat and Weather Resistance

This fabric is heat and weather-resistant. Nylon at a very normal temperature doesn’t burn. On the other hand, it can help you out even in bad weather. Due to being waterproof, nylon can save your important documents and files. If you have an umbrella that is also made of nylon. So, you are with nylon in every sphere of your life.

Mildew, Molds, Insects, and Fungi Resistance

One of the many important advantages, this is very mentionable. Sometimes we see our bags or other products made of other fibers are affected by mildew or insects but hopefully, in this case, nylon fabric products won’t face such kind of problems and that is why people like it very much.

Moisture-Wicking

Nylon is an artificial and synthetic fiber. This is why it has a good moisture-wicking ability. When you are on a morning or evening exercise, you may see the t-shirt you are wearing and if it is made of nylon, it surely lets the sweating water away and out through the shirt. That’s why nylon fabrics are good for sportswear.

Versatility

Undoubtedly, nylon is a versatile fabric. It can be blended with other fibers like cotton, wool, silk, or any other fiber. The results become amazing. Due to blending with other fibers, the resulting nylon becomes more powerful and versatile. Nowadays, nylon is used in all parts of the clothing industry and it is blended in order to increase the aesthetics and strength of the fiber.

Stretch & Elasticity

One of the most common features and advantages of nylon fabric is its elasticity. It can retain its shape and is good for wearing. Elasticity helps you move freely according to your wish. However, for a better and more comfortable wearing experience, the nylon is often blended with other fabrics namely spandex or elastane. In addition, these results bring a lot of stretchiness.

Easy Maintenance

Maintaining clothes in good shape is really a discernible matter. In terms of cotton or silk, it might be a bit tough to clean but for nylon, it is really easy like water. You can use your hands or machines to wash the clothes. After cleaning your clothes, if it is made of nylon, they will dry so quickly compared to others that are really amazing.

Disadvantages

Non-biodegradable

The first negative point against nylon is it is not biodegradable and this is why they don’t break down over a long period of time which consequences clogging up landfills. This is a bad sign for the environment. For this reason, if nylon is to be used, there has to be a way that the fibers can dispose of the soil in a short time.

Lack of Breathability

What demerit comes next is a lack of breathability. This artificial fabric does not facilitate enough airflow through the clothes. Cotton is the best to pass the airflow smoothly. That’s why cotton is the first choice.

Environmental Concerns

As the fibers of nylon are non-biodegradable, it is a threat to the greenhouse. In addition, any product made from fossils is not good for the environment. Statistics show nylon fiber doesn’t degrade naturally in a short time at least it takes 50 years’ time.

Flammability

Nylon has a high burning point and for this reason, this fabric is easily prone to burn. This can cause serious injuries. One more thing is worth mentioning nylon can melt under high iron settings. So, everybody needs to be very careful when dealing with nylon.

Health Concerns

Good health is a blessing of God. But we cannot throw ourselves into danger using harmful materials. From the starting process to the finishing process, nylon is a harmful substance due to multiple chemical reactions. As this fiber is made from different chemical forms, it increases the risk of health.

Besides, nylon fabric is non-hypoallergenic. As it is formed with chemicals, it may cause hormonal issues and create skin allergies.

How Does Nylon Fabric Impact the Environment?

The continuous production of nylon is considered a threat to the environment. The main culprit here is the raw material that is used to produce nylon. While nylon fabric is created different substances, to be exact, chemical substances are formed. However, in terms of other substances, most manufacturers use crude oil as their source of hexamethylenediamine, shortly diamine, which plays an important role in forming nylon fabrics.

Besides, it is well-established that all fossil fuels are detrimental to health. Drilling, fracking, and other methods of petroleum harvesting are also threats to ecosystems around the world. Apart from this, since petroleum is not a sustainable resource, it is required to expand the global oil industry.

Moreover, while processing the nylon fiber, a huge amount of energy, as well as harmful waste materials, are produced which leads to a global negative impact. In addition, a large amount of water is needed to cool nylon fiber which carries pollutants into the hydrosphere surrounding manufacturing locations.

The Consequences and Victims of Using Nylon

As mentioned earlier a huge quantity of waste materials is produced during the manufacturing process. Besides, a large amount of water is needed to cool the nylon fiber which threatens the surrounding manufacturing locations carrying the pollutants.

The more dangerous part is in the production of adipic acid, the secondary constituent part of most types of nylon fabric, nitrous oxide is released into the atmosphere which is considered to be 300 times worse for the environment than CO2.

And, since this artificial fiber is fully synthetic, it won’t dispose naturally in 100 years and this is why it endangers the atmosphere.

Can Nylon be Recycled?

Technically no, it can’t be recycled but thankfully some forms of this fabric are recyclable but not all waste management services recycle this substance. Unlike cotton, silk, and wool, nylon is processed chemically which is quite unnatural and is also not sustainable.

Nowadays, nylon is blended with some other fibers and this is how it has been almost impossible to recycle the materials.

Karla Magruder, a textile professional and the founder of Fabrikology International, stated that blending nylon and cotton can technically be possible for recycling but it is still in the embryonic stage. In this sense, yes, nylon is recyclable but in reality, a large amount of nylon cannot be recycled yet.

However, we hope, will get solutions to it and can save the earth.

How Can We Mitigate Nylon? Any Suggestions?

If the nylon fiber is still a continual process, there is no other option to mitigate it. We cannot anyhow escape the detrimental environmental impact caused by polymer fabrics during the manufacturing process because it is inevitable.

To protect our environment, what we can do at our best is dispose of the waste materials properly so that it doesn’t reach to the rivers or harms people. Except it, some polymer fabrics still contain trace amounts of toxic ingredients when the manufacturers make into apparel and market to consumers. So we must be aware of that too.

However, to mitigate this situation, we can take initiatives to use plant-based fiber that must be a good step.

Besides, reducing the usage of nylon and halting the continuous production would be good thinking too. We cannot stop it in one day because it has spread all over the world. Nylon has hundreds of benefits besides some bad impacts. We cannot refrain from our life instantly because it exists in our life already.

The good news is some brilliant scientists are working on it ceaselessly to find solutions so that we can use it safely and when we will find a cure, we will have the freedom to use it.

Last Words

Nylon fibers are exceptionally strong and elastic. It is even stronger than polyester fabric. The nylon fibers are incredibly tough, abrasion-resistant, and are very easy to wash. Manufacturers can dye in a wide range of impressive colors. And, to be truthful, the filament yarns provide a smooth, soft, and lightweight fabric of high resilience.

However, nylon is used in different fields basically in the garment and home furnishing industry. But, unfortunately, due to its higher price and lesser wrinkle resistance, nylon has been replaced by polyester in many garment products. Yet, its importance hasn’t diminished that much. Nylon fiber is needed in demanding applications such as tire cords, ropes, seat belts, carpets, parachutes, racket strings, sleeping bags, hoses, conveyor belts, tents, and various civil engineering materials.

So you can decide for yourself which fabric is suitable for you? What is nylon fabric – still a question? I hope I have been able to clear that up by now.