Inarguably, 600D Polyester is one of the most utilized fabrics in terms of manufacturing bags, clothes, and other necessary items. Yes, Nylon is a popular choice but, without any doubt, polyester is the most commonly used fabric after cotton.

600D Polyester is also known as the packcloth as it is considered a less expensive material. This also comes in a variety of colors so that you can pick the best one you think fits. And, due to the availability of various colors, this polyester has become the top choice for backpacks, school and college bags, and camping chairs, and so on. To make a tool bag for plumbers or a hand tool bag for electricians, 1800 PVC Denier Nylon is required.

People like nylon but in this case, they prioritize polyester over nylon because it is affordable to most of all. A proverb goes, “You get what you pay for”. This is absolutely true. If you want a good product, you must have to pay accordingly.

What is 600d polyester?

600d polyester is the most common and utilized fabric to use for multiple purposes. They have different thicknesses as well such as 600D, 300D, 400D, 500D, 210D, and others. Depending on the thickness and weight, the fabric becomes good, better, or the best. Thus, some are lightweight fabrics while some are not. For example, 210D and 300D are lightweight fabrics.

If you don’t get it yet, I would highly recommend you to understand first what Denier is. Because of all the concepts behind the measurement of yarn, the denier works directly. So learn about deniers from the below.

What is Denier and why is it important?

600D where ‘D’ stands for Denier. Denier is one of the measuring units of the thickness of yarn which falls under the category of direct yarn count system. However, Denier was originally designed to quantify the various sizes of silk strands.

Denier is very important in terms of creating fabrics because it is directly accountable for thickness, sturdiness, and durability. So fabrics with a higher denier count are supposed to be more durable while fabrics with a low denier count tend to be sheer, soft, and silky.

Now, let’s analyze more about Denier. In terms of fills compared to a microfiber, the fiber is supposed to be less than one denier which is great. This gives the filling its vaporous weight, downy feel, and delicacy. If you compare human hair which is 20 deniers with Standard Fiber’s microfibers which are typically 0.9 deniers or less, it would be a gulf difference.

So, it can easily be deduced that the denier is important because the higher the number behind the ‘D’, the higher the thickness of the fabric. In the same way, the lower the count behind the ‘D’, the lower the thickness of the fabric.

How Denier works?

As it has already been mentioned Denier is a measurement of the weight in grams per 9000m length. So the higher the denier is, the thicker the yarn would be.

Let’s understand this fact through an example. It will be clearer.

For example, 1200 deniers and 600 deniers of polyester yarn.

- 1200 denier = the weight is 1200g per 9000m of length

- 600 denier = the weight is 600g per 9000m of length

So, what can we conclude? We can understand that being the length (9000m) unchanged only the weight of the denier changed which results in the weightier the denier is, the thicker the yarn is. In this case, 1200 denier yarn is thicker than 600 denier yarn.

However, some of the other examples of direct yarn count system are;

- Tex – The weight of yarn per 1000m length

- Decitex – The weight of yarn per 10000m length

How Strong is 600d Polyester Fabric?

Due to super durability, 600d polyester is widely used in various sectors especially in the garments industry. Producing kid’s backpacks or backpacks for college students is one of the best uses of it. For military-quality backpacks, 1050D Nylon will be a better option.

In addition, backing materials for the fabric are essentially the most considerable difference. For example, the 600D polyester which has PVC backing is about 2.4 times stronger than the PU backing. Yes, need to consider all the necessary factors.

Is 600d Polyester Strong Enough?

In our daily lives, we use backpacks, camping chairs, clothes, and many products that are made from 600d polyester material. The question is- is the 600d polyester material strong enough to last long? The direct answer is- yes, it is durable and strong enough to trust it. Besides 600D Polyester, 900D, 1000D, 1680D, 1800D, etc. are great to make quality products. However, 210D, 300D, 400D, and 500D nylon are also good. The less thick the yarn is, the lower the price of the product would be.

Anyways, some organizations tested and found that 600D polyester PVC backing to tear up with 300N strength, and 600D polyester PU backing to tear up with 130N strength.

Benefits of 600D Polyester

There are some benefits of 600D Polyester. Let’s see what they are-

- Comparatively cheap price

- Durable and impressive

- Heavy-duty fabric

- Long-lasting materials

So, if you are interested in making top-quality backpacks, luggage, camping chairs, or other products, this 600d polyester material would be the best choice. You must gain its benefits.

How to Choose the Polyester 600D Grade That Suits You?

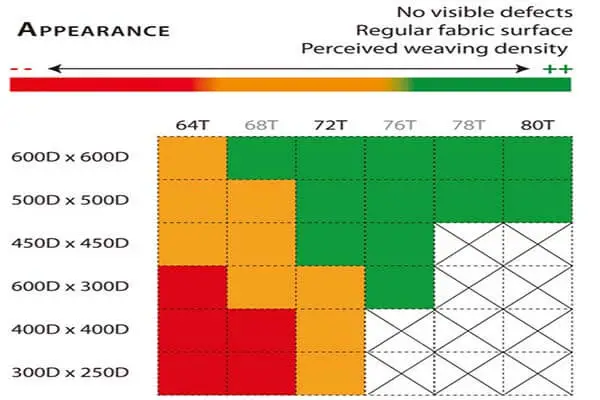

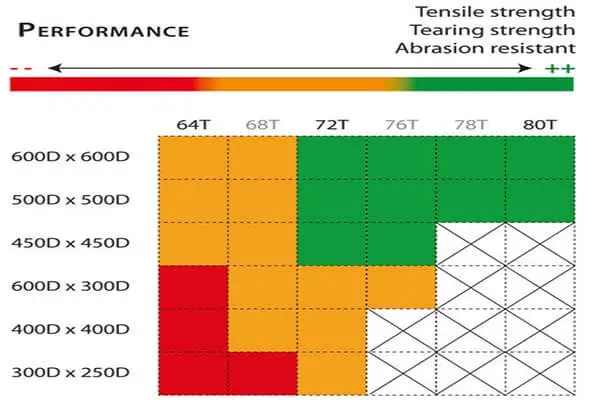

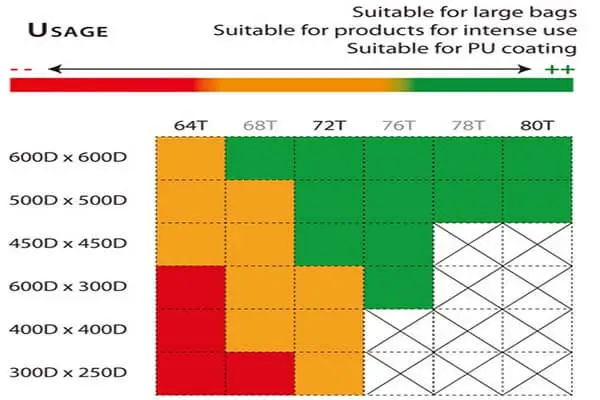

Choosing the best grade 600D material is a challenging matter because the yarn thickness and density of fabrics play a direct role in affecting the functional and aesthetic performances of your finished product. So, a wise decision will save the day.

What should you consider thoroughly for each grade of 600D?

- The mechanical performance – the mechanical performance of the fabric includes tearing, tensile strength, and abrasion resistance. No wonder, the usage of lifetime of your product is directly proportional to these values.

- The general appearance – the general appearance of the fabric that includes drawn yarn, visible density, thickness, and hand feel are the technical attributes (titration-density).

- Whether or not PU coating (polyurethane) is suitable – PU coating is a very thin layer of polyurethane that helps to keep the woven thread together and seal the finished fabric. This is also responsible for the waterproof performance of the material.

So, on the off chance that the texture thickness is too low, this liquid PU reaches out through the texture and stains the surface.

Additionally, a texture with loose weaving remains excessively weak for bigger backpacks if only supported with a thin layer of PU.

However, if you need to back your fabric with PVC, you must have to take some points into consideration:

- The cost of your product because PVC backing is more expensive than PU coating

- The weight of PVC fabric because a PVC-backed fabric is two times as heavy as the same fabric with PU coating

- Whether it has to comply with regulations such as the REACH regulation (a ‘regular’ PVC coating is not a REACH complaint, this is absolutely required at the time you place your order)

So What to Focus On To Choose 600D Polyester Fabric?

Well, considering the focal points thoroughly for each grade of 600D, we can conclude the major 3 points that we need to focus on –

- The look of your final product

- The performance of the material

- And, the target price

Indications of Performance and Possible Applications for Different Grades of Polyester 600D

Honestly speaking, if you are on to make some heavy-duty backpacks, denser materials, and heavier threads will ensure the product lasts longer than the usual time.

These kinds of heavy-duty materials are generally used for products that are intended to carry heavy loads such as tool bags for plumbers or electricians. In addition, in terms of repetitive pulls (e.g. handles of travel bags or backpack straps) of a tool bag or satchel that is subjected to daily use would be great.

However, the tables given below will indicate the performance and possible applications for different grades of polyester 600D. Understanding the table would enrich your knowledge in order to pick the best cost/performance ratio for your product.

There are 3 images here on 3 different factors. Let’s know more about it.

Image 1: Appearance

- No visible defects

- Regular fabric surface

- Perceived weaving density

Image 2: Performance

- Tensile strength

- Tearing strength

- Abrasion resistant

Image 3: Usage

- Suitable for large bags

- Suitable for products for intense use

- Suitable for PU coating

How to Identify the Quality of Your 600D?

By Asking Information:

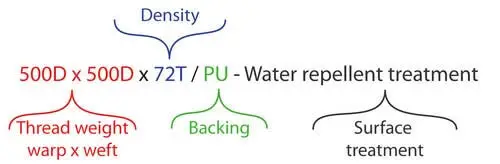

If you really don’t know the fabric, how will you approach the supplier? Well, the easiest way to approach your supplier is to ask for the features of your chosen fabric. The features could be the Deniers of the thread, weaving density, coating, and whether it is water-resistant or not.

However, if you are not able to get the complete information about the fabric, the minimum pieces of information that must be indicated to you are as follows:

“Composition …….D x ……..D x ……..T / backing — Surface finish”

Example: “Polyester 500D x 500D x 64T / PU – water-resistant treatment”

From this image you will find two important pieces of information to evaluate the quality of your 600D:

- Thread weight (Deniers) used on warp and weft

- Weaving density

By Hands-on Approach:

If you are experienced and knowledgeable enough, just follow two steps –

- Just take your thread count glass and validate the density of the weaving

- And then complete the denier of the thread to an existing standard denier

Attention

- It is not a reliable way to validate the quality of a material only by seeing the thickness of the finished fabric

- However, a thin fabric can be a reasonably thick material due to the layers of PU or PVC.

Remember, the tearing and tensile strength of a material is the backbone of a backpack’s sturdiness and it is also correlated to the quality of the woven fabric without coating. PU or PVC backings are used only to boost this performance.

Some Suggestions about 600D Materials

- A texture with an alluring cost isn’t really a good deal. However, on account of Polyester 600D, it’s anything but lesser quality.

- It is prudent to methodically demand the total details of your textures from your providers: you will actually want to make more effective arrangements with them, expect the level of waste if there were to be a few, and in particular, guarantee that the completed fabricated item will meet up to your desires.

- Regardless, it is more secure and consoling to perform basic tensile strength tests when a new material is used. In this manner, you will keep away from difficulties and superfluous issues during production.

- Purchase intelligently by picking the thickness/thread weight 600D that shows the best cost/performance proportion for your item: not important to pick a texture that will overperform and burden your value, it is safe to understand what performance and looks can be expected with less expensive density/thread weight combinations.

Last Words

A piece of 600d polyester fabric is good and strong enough to last your fabric long. This durable and heavy-duty material is waterproof and abrasion-resistant. If you are a production manager or a person who is going to purchase 600d polyester, you are cordially requested to have a look at the whole article because this resourceful article can provide the knowledge you are looking for. You can be able to recognize how to choose and pick the best polyester 600d fabric.

Image Credit: metissagesbags.com