In our daily life, polyester is one of the most utilized fabrics. From garments to small shops, polyester is seen everywhere. Without this fabric, it would remain undiscovered a very important product in our lives. But, do you know, what is polyester fabric? How it is made and where? What are its advantages and drawbacks? Do you know its properties? Don’t worry, we are going to cover everything in detail about polyester in this article.

So, before diving deep, why don’t we know about the history of how polyester was first introduced and who?

What is Polyester?

Polyester is a synthetic fiber that is derived from different substances like coal, air, water, and petroleum. It is the most commonly used worldwide fiber. Polyester fiber was developed in the 20th century.

In a general sense, polyester is a fabric or textile that is used for multiple purposes in our daily lives. It is a durable and long-lasting fiber. There are hundreds of fields where polyester is used. It doesn’t only increase the aesthetic beauty of your home but also gives you a level of standard. Being water, fire, and abrasion-resistant, this fabric has become one of the most integral parts of our life. In a word, polyester fiber has excellent elasticity, wrinkle resistance, shape retention, excellent wash-and-wear performance, and durability. In addition, this fiber is widely used in all kinds of apparel fabrics.

Chemically, Polyester fabric (polyethylene terephthalate) is a polymer that is primarily composed of different compounds. To manufacture polyester, a specific material that is commonly referred to as a type called polyethylene terephthalate (PET) is made by mixing two compounds namely ethylene glycol and terephthalic acid. Two types of polyester are usually used. They are PET (polyethylene terephthalate) and PCDT (poly-1, 4-cyclohexylene-dimethylene terephthalate). However, it looks very scientific but if you think of it is a general sense, polyester is a kind of plastic. It is well-known for its durability and relatively inexpensive to produce.

There are many categories of polyester are there such as 600D, 500D, 900D, 1680D, 1800D, and many more.

If you want to make heavy-duty backpacks or tool bags like tool backpacks for plumbers, or tool bags for electricians, you must use 1680D or 1800D fabric in order to have a great service.

Who invented the Polyester Fabric first and When?

Maybe this story is known to all who usually deal with fabrics. Nevertheless, I am expressing the story in short.

Polyester is the most commonly used synthetic fiber. Research on large molecules and synthetic fibers was started in 1926 on behalf of United States-based E.I. du Pont de Nemours and Co. This research was centered on Nylon, the first synthetic fiber.

However, soon after it, a cluster of British research chemists found interest in the du Pont studies in the years 1939-41 and conducted the research in their own way in the laboratories of Calico Printers Association, Ltd. Later on, this work was successful and resulted in the creation of the polyester fiber known in England as Terylene.

In 1946, du Pont purchased the right to produce polyester fiber in the US. Through time, the company achieved some further developmental work, and in 1951, they started marketing the fiber under the name Dracon. In contemporary times, some companies showed a severe interest in Polyester fibers and they also began to produce their own versions of the product for different uses.

Today, there are two primary types of polyester, PET (polyethylene terephthalate) and PCDT (poly-1, 4-cyclohexylene-dimethylene terephthalate). Tough to pronounce, huh? Just kidding.

What is the difference between those two? Well, first of all, PET is the more popular type is used for a wider variety of uses. Besides, it is stronger than PCDT. In addition, PET can be used alone or blended with other fabrics to make clothing.

On the other hand, PCDT is more elastic and resilient than PET. However, PCDT is used for heavier consumer uses, such as draperies and furniture coverings.

Raw Materials of the Polyester Fiber?

Polyester can be broken into two parts; Poly (meaning many) and Ester (meaning a basic organic chemical compound). The main ingredient used in it is ethylene which is derived from petroleum. However, in this process, ethylene is the polymer (the synthetic structure block of polyester) and the chemical process that creates the finished polyester is called polymerization.

The Manufacturing Process

Polyester can be manufactured in several methods. There are four basic Forms to mention. They are:

- Filament Form: has individual strands of polyester fiber and is continuous to length. It also produces smooth-surfaced fabrics.

- Staple Form: in this form, filaments are cut to short in predetermined lengths and polyester is easier to blend with other fibers.

- Tow Form: in this form, continuous filaments are drawn loosely together.

- Fiberfill Form: this form is manufactured for quilts, pillows, and outerwear.

Among these four forms, two forms are most frequently used. Those two are the Filament form and Staple form.

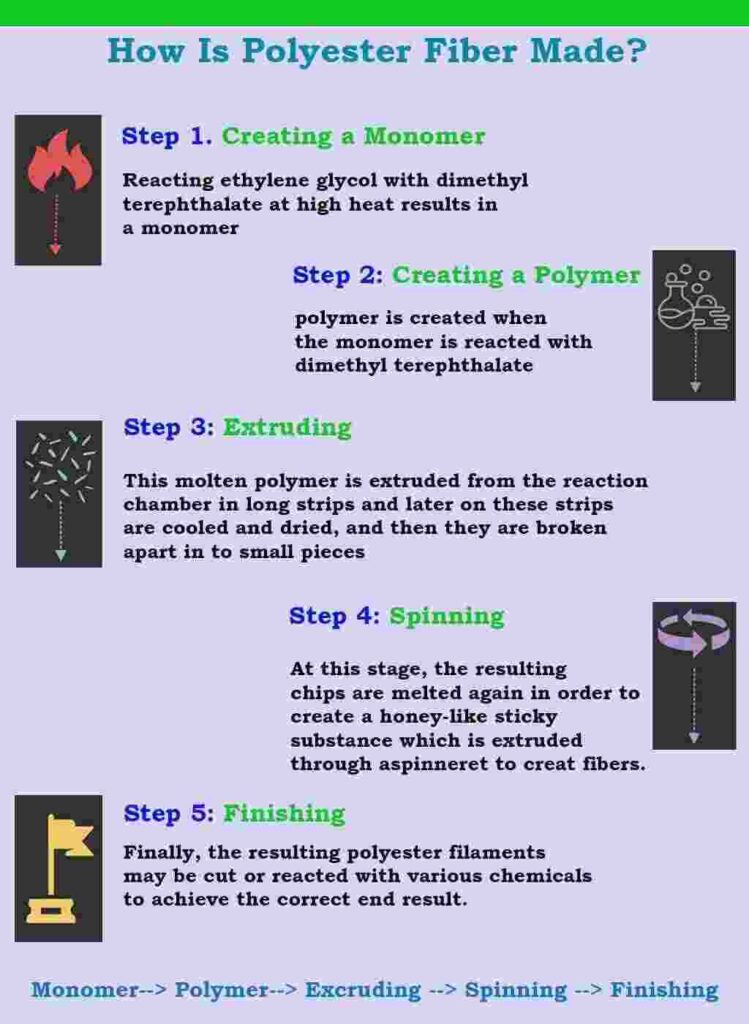

Manufacturing Steps of Filament Yarn

Polymerization -> Dying -> Melt Spinning -> Drawing the Fiber -> Winding

Manufacturing Steps of Staple Fiber

Drawing Tow -> Crimping -> Setting -> Cutting

The above infographic is great. Nevertheless, to make a better understanding a video on the manufacturing process of polyester yarn is placed below.

However, it will be easier for you to understand what is polyester and how it is manufactured if you watch this video. This video is about the polyester yarn manufacturing process. I hope it will help you a lot to have a clear understanding.

The Properties of Polyester Fiber

| Features | Results |

|---|---|

| Fabric name | Polyester |

| The fabric is also known as | Polyethylene terephthalate, PET, microfiber |

| Fabric composition | Polymers derived from fossil fuels or organic sources |

| Fabric possible thread count variations | 200-1,000 |

| Fabric breathability | Very breathable |

| Moisture-wicking abilities | High |

| Abrasion Resistance | Good to Excellent |

| Heat retention abilities | Medium |

| Absorbency | Poor |

| Stretchability (give) | Medium |

| Prone to pilling/bubbling | Medium |

| Static Resistance | Poor |

| Heat Resistance | Fair to Good |

| Wrinkle Resistance | Excellent |

| Flame Resistance | Burns Slowly |

| Country, where the fabric was first, produced | United States |

| Biggest exporting/producing country today | China |

| Recommended washing temperatures | Cold, warm, or hot |

| Commonly used in | Shirts, pants, hoodies, dresses, jackets, underwear, socks, blankets, hats, sheets, rope, upholstery |

| Tensile Strength (Tenacity) | Good to Excellent |

| Resistance to Sunlight | Good |

| Elasticity | Fair to Good |

| Resilience | Excellent |

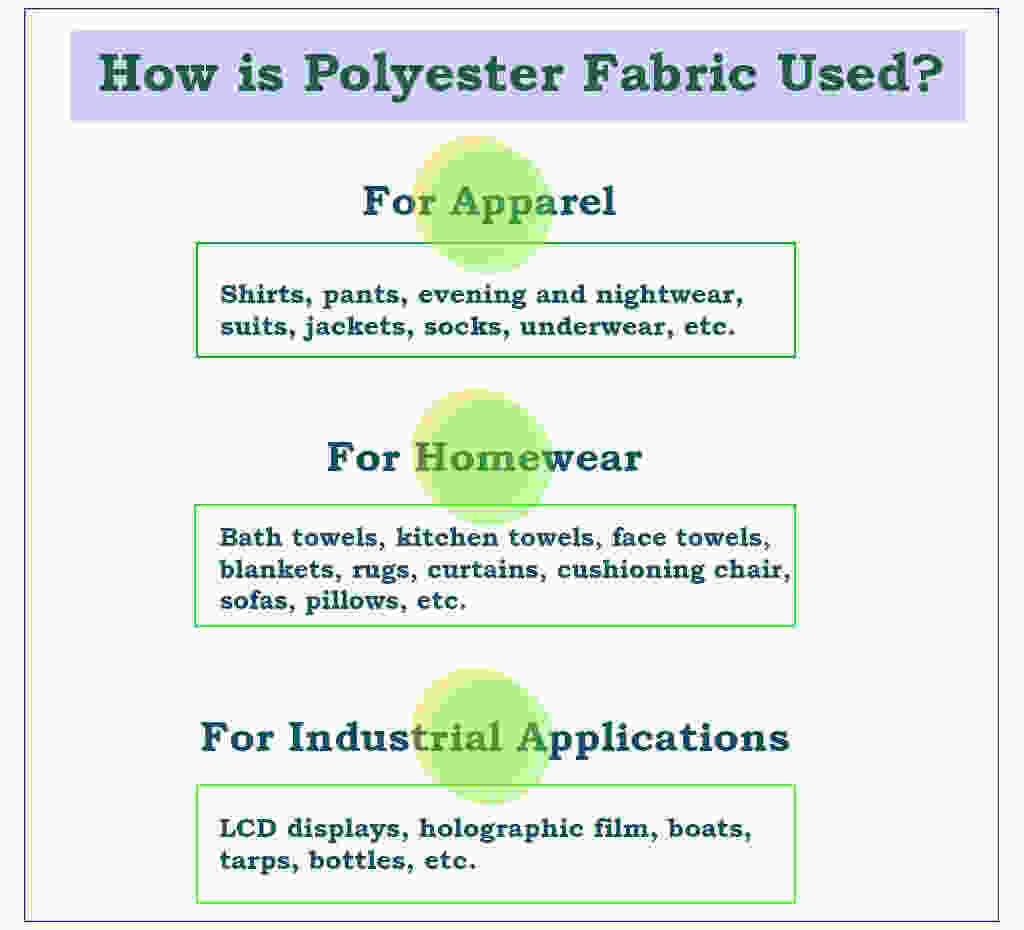

How Is Polyester Fabric Used?

Fiber form of polyester fabric (PET) is used in many different consumer applications. Do you know that PET has been used as an alternative to cotton? In some applications, polyester may also serve as a reasonable alternative to other natural fibers like wool and silk.

However, anything made from cotton or silk can also be made with polyester. Shirts, pants, evening wear, suits, jackets, socks, underwear, and hundreds of different fields, the apparel applications of polyester fabric are endless.

In addition, the use of polyester to craft various homewares is also very available. Particularly, after inventing microfiber using advanced technology, polyester is able to cover the bath and kitchen homeware categories. According to the consumer’s value covering the softness and high absorbency of microfiber in applications, hundreds of essential products like bath towels, face towels, and kitchen towels are manufactured. Besides this, to make homewares like blankets, rugs, upholstery, and curtains are mentionable too.

Apart from this, polyester fabrics are also very important for industrial applications. Primarily, the cushioning for chairs, sofas, and pillows is made with polyester. They are very popular due to the impressive and stain-resistance of this material. PET owners intend to prefer polyester products because the furs and dirt can be easily removed from polyester fabrics. And, in terms of industrial applications, polyester fiber becomes a great help in making LCD displays, holographic film, boats, tarps, and bottles.

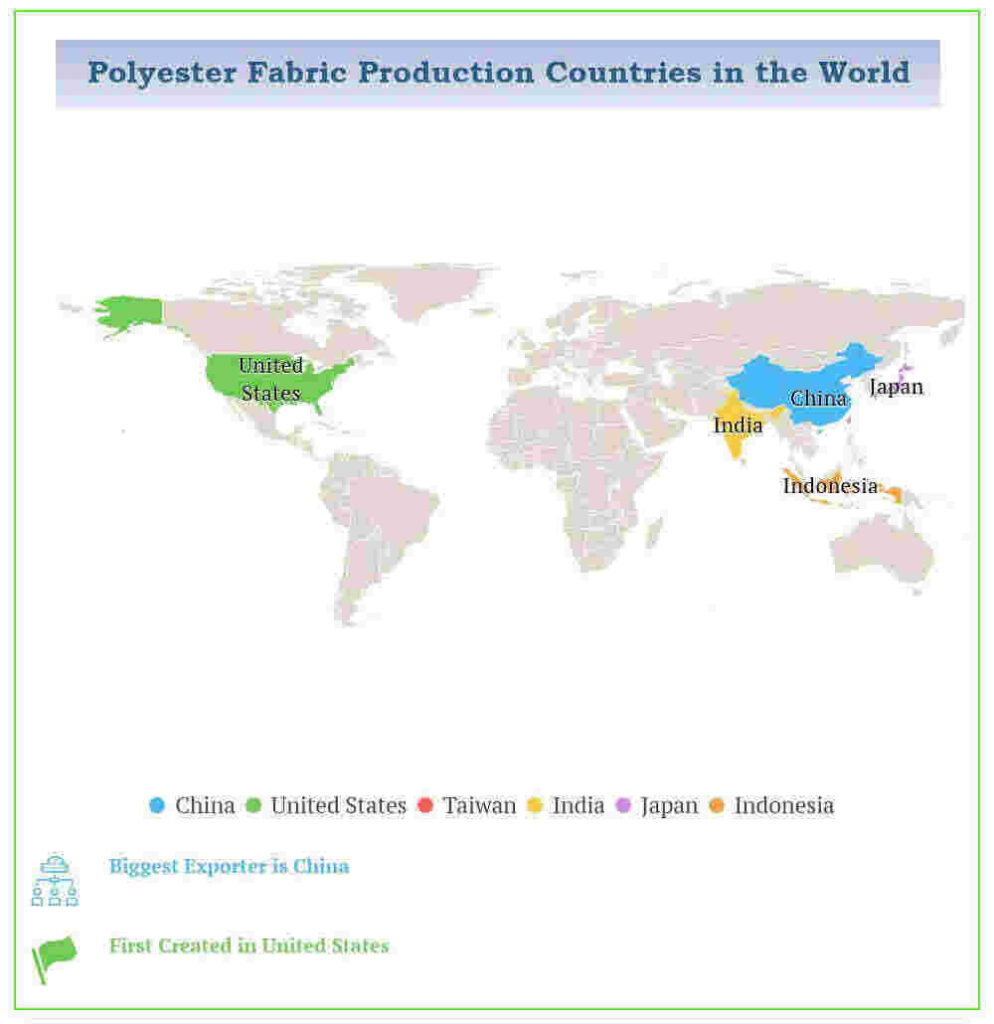

Where Is Polyester Fabric Produced?

Asia is the leader in producing PES fibers. According to a study in 2006, China is the largest polyester fibers manufacturing country. It is undeniably agreeable that China has also the world’s largest polyester market which makes this nation the hub of the international polyester industry.

China, Taiwan, Korea, India, Japan, and Indonesia play an important role in producing polyester. However, some polyester is also manufactured in the USA. The Asian countries that produce polyester fabrics hardly transport to the other continents due to huge consumption capacity.

However, in the last 20 years, PES fibers, as well as thread production, have accelerated at very high tempos (by 7.2% a year on average). It is mentionable that the share of PES fibers in Asia is 64.6% of the world’s level for chemical fibers. China is still the unconditional leader.

What Different Types of Polyester Fabric Are There?

You know about polyester fiber, right? But do you know what different types of polyester fabric are there? If not, to enrich your knowledge of polyester fabric about the three major types of this textile, you must read this whole paragraph with undivided concentration.

- Ethylene Polyester: this is also known as PET which is the most popular type of fabric on the market. However, in most cases, users understand the word “polyester” is synonymous with “PET” even though other types of polyester exist. Very funny, right?

- Plant-Based Polyester: the main differences between Ethylene Polyester and Plant-Based Polyester are biodegradable or not. The PET is non-biodegradable while the plant-based polyester is biodegradable. In this case, it is important to remember that plant-based polyester is costlier and less durable than PET and PCDT polyester.

- PCDT Polyester: though PCDT polyester is not as popular as PET, it is more elastic than the others. Due to the elasticity, PCDT is ideal for certain applications. In addition, PCDT polyester is also more durable than PET polyester. And this is exactly why, this fabric is frequently preferred for heavy-duty applications like upholstery and curtains.

Characteristics of Polyester Fibers

Polyester fibers have become an essential part of our life. From homeware to industrial applications, PET fiber is second to none. It has some impressive characteristics. Those are mentioned below:

Polyester –

- Abrasion resistant

- Very resilient (springs back into shape)

- Resists wrinkling

- Heat-resistant but very high heat can melt the fabric

- Easy to wash and wear

- Does not absorb water which can be uncomfortable when worn

- Dries very quickly

- Attracts static electricity as well as dirt and lint

- Resists oiling but if it strains, it is difficult to clean

- Often blended with cotton or even wool to add crease resistance

- Certainly does not absorb water, but it can be produced in such a way (as in polypropylene and microfibers) as to “wick” water away from the skin

- Although they do NOT absorb water, they DO absorb oil and grease. This means they are synthetics too.

- Very cheap

- is recyclable

- Has a high melting point

- Easy to maintain

- Lightweight and flexible

Polyester fabric is good to use in different sectors of our life. These characteristics are worth buying this material.

The Advantages and Disadvantages of Polyester Fabric

Since the invention of polyester, it has grown its popularity and has taken over the garment industry. This fabric is called versatile fabric due to its thousands of other applications in different fields. Besides its heart-winning position, polyester fabric has some detrimental points that indicate the dangers of worldwide fascination.

Advantages of Polyester Fabric

Low Cost in Production

What every company focuses on first is the low-cost cut in production. Fortunately, in this case, the polyester production cost is lower than manufacturing cotton and wool. It can be mass-produced in enormous quantities at a lower cost. If the product cost is low, the consumers can have it at an affordable price too. Lowering the cost to all is the biggest advantage of polyester.

Durability in Use

The long and stable polymers of polyester fabric make this incredibly strong, sturdy, and resilient. Besides, polyester clothing can easily protect against abrasion from machine washing and doesn’t require special care. It is really true that the durability of this fabric has made it popular especially for outdoor clothing.

Elasticity in Nature

Due to its highly resilient nature, polyester snaps back into shape after stretching. This advantage of elasticity allows you freedom of movement while you are wearing it. For comfortable wearing, polyester is often blended with other fabrics such as spandex or elastane. It brings the fabric a lot of stretchiness.

Versatility

Polyester has its own properties but when it is blended with other fabrics, its true versatility is exposed. This fabric has the ability and tendency to blend with another fabric and it becomes versatile and awesome. You can tell, it has the strengths of multiple kinds of fibers in one fabric. You may know that Polyester has been subtly penetrated in all parts of the clothing industry by sneaking into many other famous textures as a blending.

However, amongst all the blending fabrics, one of the best-known polyester blends is poly-cotton. This one has incredibly taken over a lion’s share percentage of the t-shirt market. Moreover, a cozy polyester-spandex blend is perfect for creating yoga pants and workout gear.

Heat Resistant

Polyester fabric is highly flame-resistant. It takes a lot to make polyester actually burst into flame. For this specific feature, polyester is one of the most popular fabrics for use in children’s sleepwear. To be honest, polyester has high standards for heat resistance.

Please Note: The heat resistance of polyester doesn’t mean it does not melt. Actually, it melts at high heat.

Moisture-Wicking

Polyester being synthetic has moisture-wicking abilities. For example, if you wear a polyester T-shirt on your morning or evening jog, you may see the fabric will let the sweating water away and out through the shirt. So, undoubtedly it is a good fabric for sports or gym.

Weather Resistance

Polyester is a weather-resistant fabric. Does it seem to you ridiculous? No, actually. In fact, polyester is really weather-resistant. Well, if water falls on your polyester shirt, know that the water will bead on its surface instead of soaking through.

It doesn’t mean that water cannot penetrate through polyester. Enough water pressure eventually penetrates through the fabric which means polyester is not waterproof though, in this case. The important information is that the denser the thread count is, the better the probability of water resistance is.

However, you should know that polyester often serves as one of the layers in jackets and coats to prevent water from coming in. So, it is in fact weather-resistant.

UV/Light Resistant

Polyester fabric provides high UV protection. As the sunlight can pass through it that means it can reach you. For this reason, you must be careful in taking necessary protective steps such as wearing sunscreen.

Easy Maintenance

One of the best qualities of polyester is its easy care and maintenance. As it dries quickly, you can easily hang it up to drip-dry in your shower. At that time all the water will wick away and your clothes will dry in a few minutes. Besides, polyester is machine washable and can be dry cleaned.

In addition, polyester is very wrinkle-resistant and this is how it retains its shape. Apart from this, due to being stain-resistant, it does not absorb liquids, especially water.

Comfortability

Before wearing any dress what waves across your mind is comfortability. The soft fabric may be a mix of cotton and cashmere that feels light, silky, supple, and comfortable to your skin.

Disadvantages of Polyester Fabric

Non-biodegradable

The first demerit of polyester synthetic is it is non-biodegradable which means they don’t break down over time and clog up landfills. This is not good and the environmental impact is certainly negative. So until it is created biodegradable chemically or made any process, it should be avoided till then.

Lack of Breathability

The biggest and top of all complaint about polyester is its lack of breathability. Polyester, a synthetic fiber that is essentially plastic do not facilitate airflow like other fabric. In this case, cotton becomes the first choice due to its breathability and comfortability.

Lack of Moisture Absorption

As polyester is a non-absorbent material, it does not absorb the sweat from a person’s skin. And that is why, in hot or humid weather, polyester clothes cling to your sweaty skin which is really bothering and unpleasant.

However, athletics try to avoid this issue. Polycotton has the moisture-wicking ability of polyester with the breathability of the cotton. It’s kind of hybrid. This process of polyester mitigates the stickiness of 100% polyester and the dampness of 100% cotton.

Environmental Concerns

The production process of polyester is greatly involved in greenhouse impact. Besides, any product made from fossil fuels is not sustainable.

On top of that, polyester is also not biodegradable. Some statistics show that this polyester fabric does not decompose even over a period of 50 years!

Flammability

We know polyester has a high burn point, it is able to melt more easily than you might think. This property can cause serious injuries.

One thing that you also need to know is that polyester can melt under high iron settings. So, we all have to be very careful when we iron our clothes, especially polyester clothes.

Holds Odors

This reason is very easy to guess. While polyester has a breathable problem, it can hold onto odors.

Static Electricity

Due to chemical reactions, polyester can hold a static charge that can cause issues with static electricity. You can observe it yourself especially when if you have long hair and you just have taken off a winter coat, you see the hair tries to cling to the coat.

Health Concerns

Polyester fabric is non-hypoallergenic. As it contains chemicals, it may cause hormone issues and create skin allergies. This issue sometimes makes a big deal.

What Can You Use Polyester For?

Despite some disadvantages, polyester is a widely-used product all over the world. For hundreds of thousands of purposes, this synthetic is used. From home to big industry, this product can be seen. In addition, this can be used as household products, upholstery, and carpeting.

Polyester is used in:

Polyester is used worldwide and for different purposes. Let’s see what polyester is generally used for.

- Fashion

- Sportswear

- Fleeces

- Upholstery

- Rugs and carpets

- Coats and anoraks

- Bedding such as sheets, duvet covers, and sleeping bags

- Footwear

- Fillings for duvets (due to its insulating properties)

- Sewing threads

- Soft furnishings and upholstery

- Textiles

- Luggage and other bags

It is true that listing of uses in the different sectors won’t be enough. Besides these, there are hundreds of fields where this synthetic fabric is used. But yes, the mentioned sectors are the most commonly used polyester.

Is Polyester Sustainable?

To answer directly this question, No, polyester fabric is not sustainable because it is derived from petroleum. Statistics show that in order to produce polyester, billions of barrels of oil are needed every year. In a word, the use of any fossil fuel is not sustainable in the long term.

In addition, polyester is a synthetic that is non-biodegradable. This is how an increasing amount of polyester textile production multiplies plastic waste in landfills around the world.

Moreover, due to cheap cost, this material is used everywhere which is both the greatest strength and the strongest weakness. It is obvious that mass production often leads to mass pollution which threatens the environment.

Additionally, it is a matter of great concern that recent studies showed is polyester fabric also leads to micro pollution. Micropollution happens through washing polyester fabric that washes away tiny plastic fibers into the wash water. However, this is totally undeniable that these microfibers cause a significant amount of micropollution.

Being concerned enough about this matter, some renowned companies like Adidas and Ikea strive to use a significant percentage of recycled polyester in their clothing lines.

Can Polyester be recycled?

Polyester material recycling has been developed utilizing clear plastic water containers, or PET as the raw material, a source of plastic that would in some way go into landfills. For instance, materials like wool are produced using reused polyester which is utilized by outdoor clothing makers. Patagonia, Marks & Spencer, and other style brands are very notable for utilizing reused polyester in their items. Teijin is an organization in Japan that fostered their own polyester reusing framework back into polyester texture, for re-use as attire.

However, this is not always the case. Polyester fabric is now mixed with some other materials such as cotton and this is how the recycling process has been very difficult and even sometimes impossible.

Karla Magruder, a textile professional and the founder of Fabrikology International, stated that in some cases recycling polyester is technically possible by blending with polyester and cotton. But unfortunately, it is still at the pilot level. She also added that the core challenge is to find processes that can be scaled up properly and we are not there yet.

So, in this sense, yes polyester is recyclable. But regrettably, a large amount of polyester cannot be recycled yet. The good news is many institutions are ceaselessly working on a solution. However, a scalable one hasn’t been found yet.

How Does Polyester Fabric Impact the Environment?

Polyester fiber generally has a negative impact on the environment. It is a matter of regret that from its production to its use to its disposal, polyester has unfortunate environmental impacts at every stage of its use cycle.

We all know that the main source of producing polyester is raw materials, to be specific petroleum. These fossil fuels are, beyond doubt, limited resources. In addition, these materials are used for vital energy and plastics production applications.

However, the process of refining crude oil into petroleum can lead to toxins in the environment that can harm living things not only in the water but also on the land.

The next level after refining the oil is to produce ethylene which essentially requires further refinement processes. This extraction process stage is also wasteful and harmful to the environment.

Now the next level comes. At this level, to transform ethylene into polyethylene terephthalate fibers a process is maintained and the result comes with more harmful synthetic byproducts. The final level proceeds with dyes and treatment processes. This procedure needs to involve the surrounding environment which finally leads to poisoning the area’s ecosystems.

The Consequences and Victims of Using Polyester

First of all, the usage of polyester often has significant social and cultural costs. Due to cheaper costs in production, the producers are engaging in slave labor. The polyester workers are gradually exposed to toxic chemicals that may cause different kinds of incurable diseases such as neurological damage, cancer, or other potentially fatal conditions.

Moreover, the major polyester-producing companies are becoming enriched by exploiting uneducated people in impoverished countries.

However, the processing factors of harmful impacts on the environment are not all here. According to a groundbreaking 2014 study, washing polyester fabrics by hand or even in washing machines releases tiny synthetic microfibers into the water supply that is quite detrimental to health.

The alerting matter is acrylic fabric was found to be the worst offender in terms of microfiber pollution while polyester came in as a close second. The health of marine life is a harmful way for microfiber pollution. It also contaminates drinking water in locations all over the world.

Should We Reject Polyester?

This is a very tough question to answer. Rejecting polyester has many potential reasons. If you have already read everything, you may make a decision. Let’s focus again.

As polyester is not biodegradable fibers like wool, cotton, or silk, it does not naturally degrade in the environment. Besides, no other methods have been invented yet that this synthetic would dispose of in a short time. So, it’s also impossible to know exactly how long polyester will remain in the Earth’s ecosystems before it degrades.

Besides, from processing to use, polyester has a negative impact on lives as well as the environment which is quite delirious for animal’s life.

But, rejecting a material that has already reached people all over the world is not an easy task. There are some hopes to find its solutions.

So, What Should We Do? Any Suggestions?

Every product has good and bad benefits. We have focused perfectly on how polyester has negative impacts on our life and the environment too. It has some strong benefits that help to make our lives easier and more comfortable. This synthetic fabric has been used for almost 100 years and it is still a continual process.

Some bright scientists are trying to solve this problem but till then we must need to be more careful so that we may not endanger our life for some mistakes. There are many options to choose from over polyester.

Apart from this, the plant-based polyester fiber would seem to be a step toward reversing this unfortunate state of affairs.

Reducing the usage of polyester as well as production would be a great decision and suggestion both for users and producers in order to keep the earth safe.

Last Words

Polyester fiber has existed in our lives thoroughly. It is now a very difficult step to keep away from us. Aside from its negative impacts, this synthetic fabric is a revolutionary change and invention in fashion and every sphere of life. The way to find how to biodegrade is the best solution for now. For these reasons, scientists can be a vital part of it. Hundreds of advantages of polyester would have made our lives so much more comfortable and easier. I hope if you read this whole article, you can know, what is polyester fabric, as well as, its advantages and disadvantages. I have tried to cover the best possible factors to make you satisfied.