Choosing the right luggage material can be a difficult decision. There are many different types of luggage materials, and each one has its own set of pros and cons. You’ve probably heard about polycarbonate and ABS luggage before. But do you know which one is the best luggage material? Well, Polycarbonate and ABS are two of the most commonly used materials for luggage. But the question is – which one is better? In this article, we are going to discuss Polycarbonate Vs ABS Luggage. If you are with us, at the end of the discussion you will, at least, know which one is the best to pick for travel and other purposes.

Luggage is one of the most essential items of a traveler’s travel kit. It is used for storing personal belongings during the trip and to protect them from the various elements of the environment. The best luggage material should be light, durable, strong, and easy to clean. But the most important thing is that it should not be flammable.

Polycarbonate Vs ABS Luggage

There is no doubt that polycarbonate is the best material for making luggage. However, it is not the only material you can use. In this article, we will compare the two most popular materials: Polycarbonate vs. ABS Luggage. We will also discuss the pros and cons of each material.

Since we are talking about Luggage, it is a necessity for every traveler. Carrying luggage is a good way to carry your personal belongings, but it’s also a great way to make your traveling experience more enjoyable. However, with so many different types of luggage available, it can be difficult to know which one will work best for you. While there are many things to consider when choosing the right luggage, one of the most important things to look for is the material used to make the case.

Some of the most common materials include polycarbonate, ABS, polypropylene, and nylon. Each of these materials has its own set of pros and cons, and it’s important to know what you’re looking for in a case before making your purchase.

However, we all know that the best luggage is the one that we carry with us. But what if we had to choose between carrying polycarbonate or ABS luggage? Which one would be better for our travel needs? Let’s find out.

Polycarbonate luggage Material

Polycarbonate (PC) is a strong, tough plastic used to make everything from bulletproof glass to high-end sports equipment. It’s also a material used in the manufacture of a variety of consumer products including luggage.

In addition, Polycarbonate is a durable and lightweight plastic that’s used in a wide range of applications including, but not limited to, the manufacture of durable goods such as luggage. While polycarbonate is the most widely used material in the production of luggage, it isn’t the only material that can be used. There are many other materials as well that can be used to make a suitcase and backpacks.

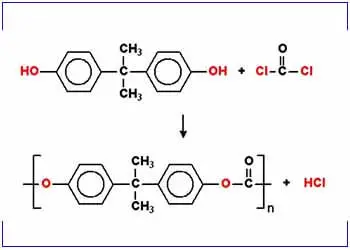

Moreover, Polycarbonate is a thermoplastic polymer that’s used to make a variety of products, including eyeglass lenses, plastic bottles, and some types of safety equipment. It’s also used to make the tough, scratch-resistant exterior of many plastic products, such as computer monitors and televisions. However, polycarbonate can be expensive to produce and can be difficult to recycle.

Some Best Polycarbonate Luggage

ABS Luggage Material

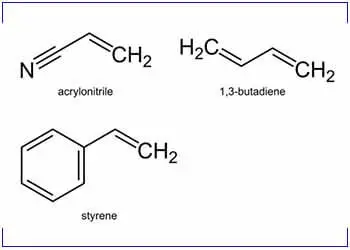

Acrylonitrile Butadiene Styrene (ABS) thermoplastic resins is an integration of three different plastic materials namely Acrylonitrile, Butadiene, and Styrene. Mixing them together, ABS plastic becomes a good and impact-resistant material to make durable products that need to be processed and shaped, and that may also have a gloss surface.

However, each monomer type has its own properties. Acrylonitrile monomers are very versatile, they are strong and tough, and so they make good materials for tires, fabrics, and plastics, as well as adhesives and paints while butadiene provides good impact resistance. Furthermore, styrene provides heat resistance, processability, color, and hardness. ABS can be formed using injection molding, so it is suitable for small-scale production.

In addition, it has good impact resistance, good mechanical properties, and good thermal properties. In the area of ABS, these properties make it versatile enough for a wide variety of applications, from pipes and instrument housings to automotive panel components and hand tools.

In reality, Polycarbonate is much more expensive than Acrylonitrile Butadiene Styrene (ABS) plastic. ABS polymers are used to provide rigidity and impact resistance.

Some Best ABS Luggage

Polycarbonate luggage Vs ABS Luggage Materials– Side-by-Side Comparisons

There is a big debate among people who are looking for the best luggage material. People are asking this question, “What is the difference between polycarbonate luggage and ABS luggage?” The answer to this question is that they are two different materials, but one can be a better choice than the other. Let’s see what each one has to offer.

There are two types of luggage available in the market today, which are Polycarbonate (PC) and ABS. The main difference between these two is that PC has a higher strength than ABS and hence it is more durable and better. It is also lighter in weight.

Well, both of these materials are widely used in the production of luggage. They are great materials for making luggage.

Polycarbonate is a thermoplastic material that can be used to make everything from bottles to hard plastic. It has many advantages over other materials including high impact resistance, thermal stability, and clarity. It is also an environmentally friendly material that does not release toxic fumes when heated. Polycarbonate is often used in the manufacture of safety equipment such as helmets and goggles. It is also a material that is used to make medical equipment and devices.

On the other hand, ABS is excellent for indoor applications such as desktop electronics. In addition, ABS is heavy, but it’s a good choice for most indoor applications. It’s also durable, lightweight, and easy to mold into different shapes. In fact, ABS is much less expensive than polycarbonate. ABS plastic has less resistance to industrial chemicals and extreme conditions than polycarbonate.

Core Difference between polycarbonate and ABS in luggage

In the debate of Polycarbonate vs. ABS Luggage, we are going to create a table to show the core differences between Polycarbonate luggage materials and ABS Luggage materials. So let’s find it.

| Factors to Consider | Polycarbonate Luggage Materials | ABS Luggage Materials |

| Durability | More durable | Less durable |

| Weight in terms of Luggage | Light | Lighter |

| Price | Costly | Cheaper |

| Popularity | More Popular | popular |

| Design | More flexibility with styles and textures | Less flexibility with styles and textures |

| Impact resistance | Better Impact resistance | Good Impact resistance |

| Tensile strength | Polycarbonate (4000 psi) has less tensile strength than ABS | ABS (5500 psi) has more tensile strength than Polycarbonate |

| Rigidness | Less prone to crack | More prone to crack |

| Other Properties | Excellent creep resistance, very good dimensional stability, excellent impact, flexural properties good electrical characteristics, etc. | Impact resistance, good processability, good mechanical properties, high heat distortion temperature, gloss property, etc. |

| Applications | It can be used vastly in many fields such as for the manufacture of lenses, windshields, containers, light fittings, compact discs (CD), pump impellers, helmets, small, appliances, trays, etc. | Are used in many sectors such as for the manufacture of piping and fittings, components of office automation equipment, inner door cabinets of refrigerators, bathtubs, door covers, etc. |

| Hardness and Flexibility | Polycarbonate is extremely hard, brittle, and not flexible. | ABS is hard and flexible due to the rubbery part. |

| Processability | Polycarbonates require low processability. | ABS has good processability. |

Comparing ABS and PC for Molding and Machining

| Property | ABS Molded | ABS Machined | PC Molded | PC Machined |

| Heat deflection | 215°F (102°C) | 214°F (101°C) | 280°F (138°C) | 280°F (138°C) |

| Tensile strength | 6,091 psi (42MPa) | 6,100 psi (42MPa) | 10,442 psi (72MPa) | 8,000 psi (55MPa) |

| Elongation at break | 30% | 40% | 100% | 50% |

Mechanical Properties of ABS/PC

| Property | Value |

| Tensile strength | 5,900 psi (41MPa) |

| Tensile modulus | 278,000 psi (19GPa) |

| Tensile elongation | 6% |

| Flexural strength | 9,800 psi (68MPa) |

| Flexural modulus | 280 psi (19GPa) |

| IZOD impact notched | 3.7 ft-lb per in (196 J/m) |

| IZOD impact un-notched | 9 ft-lb per in (481 J/m) |

Build orientation on long edge side. The properties in this table are from Stratasys using their FDM technology.

Click here to know more.

ABS Vs Polycarbonate Luggage – Which One Is the Best Luggage Material?

In the past few years, there has been a lot of hype surrounding the advantages of polycarbonate over ABS. Now, we will try to elaborate on the difference between polycarbonate and ABS luggage materials so that which one should be taken can be defined.

To be truthful, Polycarbonate is better suited for a lot of reasons. First of all, it is lighter and cheaper than ABS. Secondly, it has a very high strength-to-weight ratio, and it is less prone to breaking than ABS. Thirdly, Polycarbonate also has a higher impact resistance than ABS.

So, in this section, we will discuss why polycarbonate is better than ABS. We will also be comparing the pros and cons of both materials.

If you’re looking for a durable and reliable luggage material, you may want to consider polycarbonate. It’s a very versatile material that can be used in a wide variety of applications, including car dashboards, bathroom fixtures, and even aircraft interiors. But what if you’re looking for something more durable, but still lightweight? Then you might want to consider using a material like aluminum alloy. Both materials are highly durable, lightweight, and affordable, but which is better?

For years, the conventional wisdom was that polycarbonate was the better material to use for luggage, but it turns out that ABS is the superior choice for many applications as well. Polycarbonate is a thermoplastic material made of carbon atoms and hydrogen atoms that are linked together. It is used for a wide variety of items such as eyeglass lenses, compact discs, and car windshields. It has excellent impact resistance and high heat and light transmission. Polycarbonate can be molded into a wide variety of shapes and is resistant to chemicals, oils, grease, and stains.

Besides, for a greenhouse that is likely to encounter temperatures above or below freezing, humidity levels, or any other challenging conditions, the right choice of the enclosure is a polycarbonate greenhouse.

So, Yes, Polycarbonate luggage material is certainly better than ABS luggage material.

Frequently Asked Questions

1. Is ABS the same as polycarbonate?

No, ABS and polycarbonates are both plastics but they have different structures. They are different in terms of their properties. ABS consists of three properties, which are acrylonitrile, butadiene, and styrene.

2. Which is better, ABS or polycarbonate luggage?

Both of the materials have demands in the market. If you ask for the best choice, it will actually depend on the price and then the quality, durability, design, and other properties. Well, if you consider all of them and if you have a flexible budget, Polycarbonate materials as well as the products such as luggage, briefcase, and bag, made from it would be the best choice.

3. Which luggage material is the most durable?

Between the two options of Polycarbonate and ABS, the most durable material would be polycarbonate. But if you are asking overall, in this case, Aluminum would be the best to pick because it is light in weight and durable but the most costly option.

4. Are hard or soft suitcases better?

There are advantages and disadvantages to both sides. It depends on your circumstances and what features are important to you.

A hard suitcase offers better protection for the contents, greater durability, and better security than a soft suitcase. They aren’t flexible, so they are not very useful for a business traveler.

Flexible luggage is more comfortable and durable than hard luggage; however, it is not as easily damaged and is not as durable. It’s also more vulnerable to theft because it’s not as well-protected as cash and credit cards.

Final Words

In conclusion, in the battle of Polycarbonate Vs ABS Luggage, Polycarbonate luggage is one of the most popular types of luggage due to its lightweight, durability, and ease of cleaning. In addition, Polycarbonate is a tough and durable material that’s commonly used in everything from eyeglass frames to bulletproof vests. It’s also a great choice for luggage. Because of its durability, it’s ideal for luggage that will be exposed to a lot of wear and tear. The material used for making polycarbonate is BPA-free. However, in the past few years, many people have started to use polycarbonate luggage because of its benefits.

Read Related Articles

- How to Measure Luggage: Best Methods Recommended

- Luggage Size Guide [Size Chart and Recommendations]

- Backpack Checked Luggage? [6 Pro Tips]

- Largest Luggage Size for Check-in [Latest Information]

- Best Backpacks with Lots of Pockets

- Backpack vs Shoulder vs Stick Vacuum – What Are the Differences?

- Uprights vs Backpacks – The Wise Pick

- How to Protect Luggage from Theft

- How to Clean Fabric Luggage

- Do Airlines Prefer Hard or Soft Luggage?

- Spinner Vs Roller Luggage